How Adams Driveshaft's supports the the Matt's Offroad Team

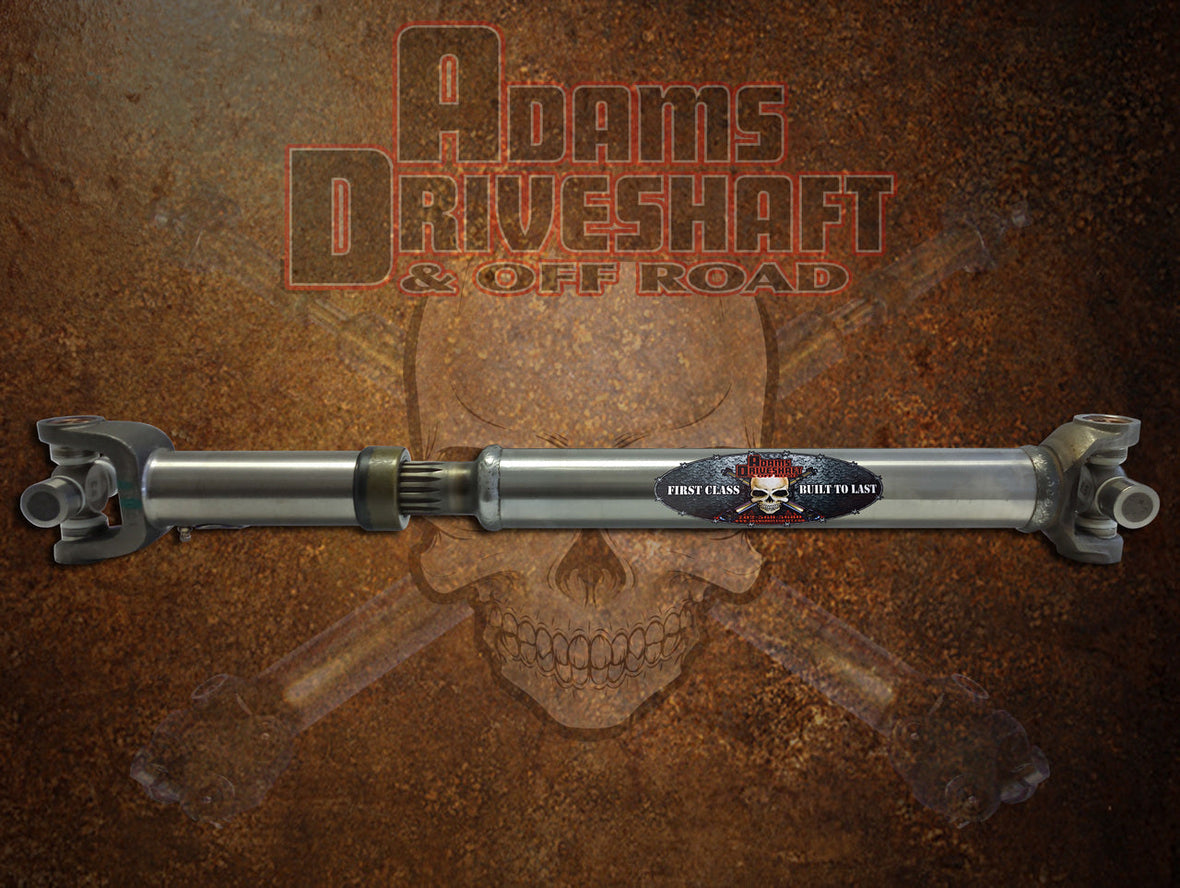

Adams Driveshaft: Crafting Custom Driveshafts for the Ultimate Wrecker

When you’re building a one-of-a-kind off-road recovery rig, standard parts just won’t cut it. That’s exactly the challenge Matt’s Offroad Recovery faced while assembling their custom wrecker. From its frame to its drivetrain, everything was built from the ground up, meaning off-the-shelf driveshafts weren’t an option. That’s where Adams Driveshaft stepped in.

Our team was tasked with designing and fabricating custom driveshafts that could handle extreme torque, unpredictable terrain, and the unique constraints of the wrecker’s layout. This wasn’t a bolt-on job—it required innovation, precision, and a serious commitment to durability.

Building Driveshafts for a Rig That Didn’t Exist

Matt and his crew needed driveshafts that could work within the tight clearances of their custom build while also delivering maximum strength. We worked closely with them to develop a solution tailored to their specific needs.

The result? A set of driveshafts built with billet 300M components, designed for exceptional toughness in the harshest recovery conditions. Every U-joint was upgraded to 1480 or 1550 series, eliminating weak points and reinforcing the entire system. We also incorporated oversized splines—so strong that Matt jokingly compared them to the ones used by Optimus Prime.

Beyond strength, the driveshafts needed to fit seamlessly within the wrecker’s complex undercarriage. To make that happen, we engineered a custom carrier bearing, designed to work with the increased torque load while maintaining proper alignment.

Tight Spaces, Big Solutions

One of the biggest challenges was making sure the driveshafts had enough clearance to function properly. With limited space to work with, the team at Matt’s Offroad Recovery had to make a few strategic modifications—precision grinding in key areas and reinforcing sections to maintain balance and integrity.

Once installed, the driveshafts were tested under different conditions. With proper phasing and balanced angles, they delivered smooth operation across high and low gear settings. Everything locked into place, shifting between two-wheel drive and four-wheel drive without a hitch.

The Road to Recovery—Now Stronger Than Ever

With the new driveshafts in place, the wrecker is nearly ready to hit the trails and tackle some of the toughest recoveries out there. The combination of oversized splines, high-strength materials, and custom engineering guarantees that this drivetrain won’t just survive the extreme conditions Matt’s team faces—it will thrive in them.

At Adams, we don’t just build parts—we deliver solutions. Whether it’s a fully custom wrecker, and off-road machine, or simply an everyday commuter, we work with builders to create driveshafts that match their needs, no matter how complex the challenge.

Matt’s Offroad Recovery put our work to the test, and we’re proud to be part of a build that pushes the limits of off-road performance. Stay tuned to see more of our custom designs and builds, and check out our site to find your next durable driveline.

Check Out The Full Video Here: